There are several effective methods to achieve professional-looking 3D prints. The best approach depends on your material type and desired finish. Here's how to get great results with different materials.

PLA Smoothing

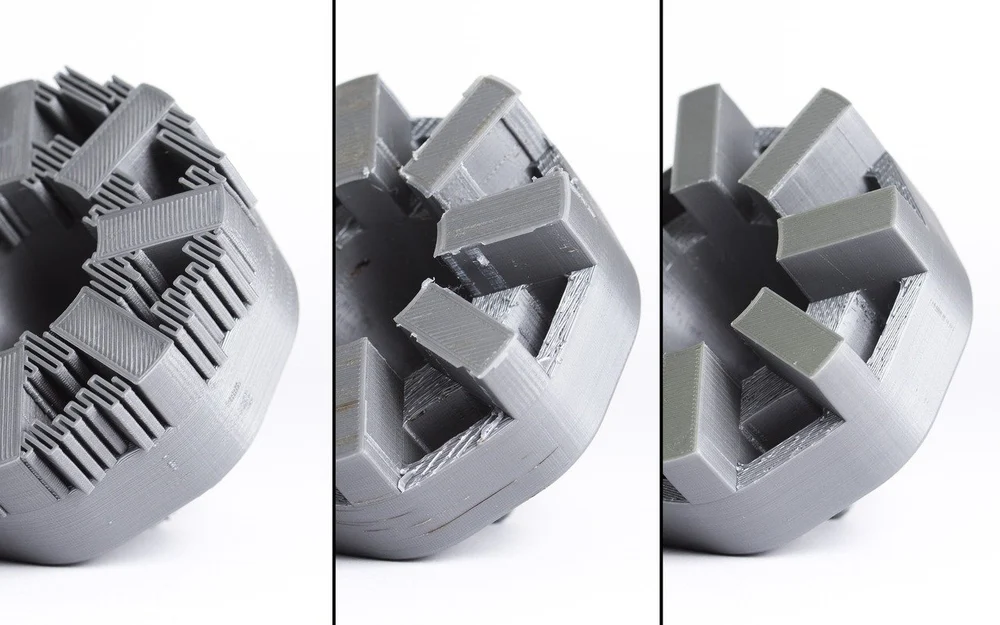

Sanding Method

Sanding is the most reliable method for PLA prints. Begin with coarse-grit sandpaper (150-220) and work your way up to finer grits (600-2000). Wet sanding produces better results and reduces dust. Work in circular motions to prevent visible patterns, and take your time - rushing the process often leads to uneven results.

Filler Primer Technique

Start by thoroughly cleaning your print to remove any dust or oils. Apply thin, even coats of filler primer spray, allowing each layer to dry completely (about 15-20 minutes). Light sanding between coats helps achieve a glass-like finish. Most prints require 2-3 coats for optimal results.

ABS Smoothing

Acetone Vapor Method

This technique creates a glossy, smooth finish but requires careful handling. In a well-ventilated area, place your print in a sealed container with a small amount of acetone at the bottom (don't let the print touch the acetone). The vapor will slowly smooth the surface. Monitor closely - over-exposure can damage detail.

Cold Vapor Method

For more control, use paper towels soaked in acetone placed around (not touching) your print in a sealed container. This slower process allows better control but typically takes 1-2 hours. Check progress every 15 minutes.

PETG Smoothing

Heat Gun Technique

Using a heat gun on low setting, carefully pass it over the print's surface, maintaining constant motion to prevent warping. Keep the gun about 6 inches away from the surface. This method requires practice but can produce excellent results.

Post-Processing for All Materials

For any smoothing method, proper preparation is crucial. Clean your print thoroughly before starting. Remove supports carefully to avoid damaging the surface. If using chemical methods, always work in a well-ventilated area and wear appropriate safety gear.

Advanced Finishing

After basic smoothing, consider additional finishing steps for professional results. A clear coat can protect your work and add shine. For painted prints, use automotive primer before applying paint for better adhesion and smoother results.

Remember that smoothing is often a gradual process. Taking your time and being patient will yield better results than rushing through the steps. Start with less aggressive methods and progress to more intensive techniques as needed.

For display pieces or functional parts that require precise dimensions, test your chosen smoothing method on a similar test print first. Some methods, particularly chemical smoothing, can affect the size and structural integrity of your print.

Every printer and filament brand may respond differently to smoothing techniques, so don't be afraid to experiment and adjust these methods to find what works best for your specific situation.